CN

Products

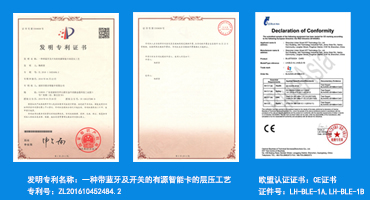

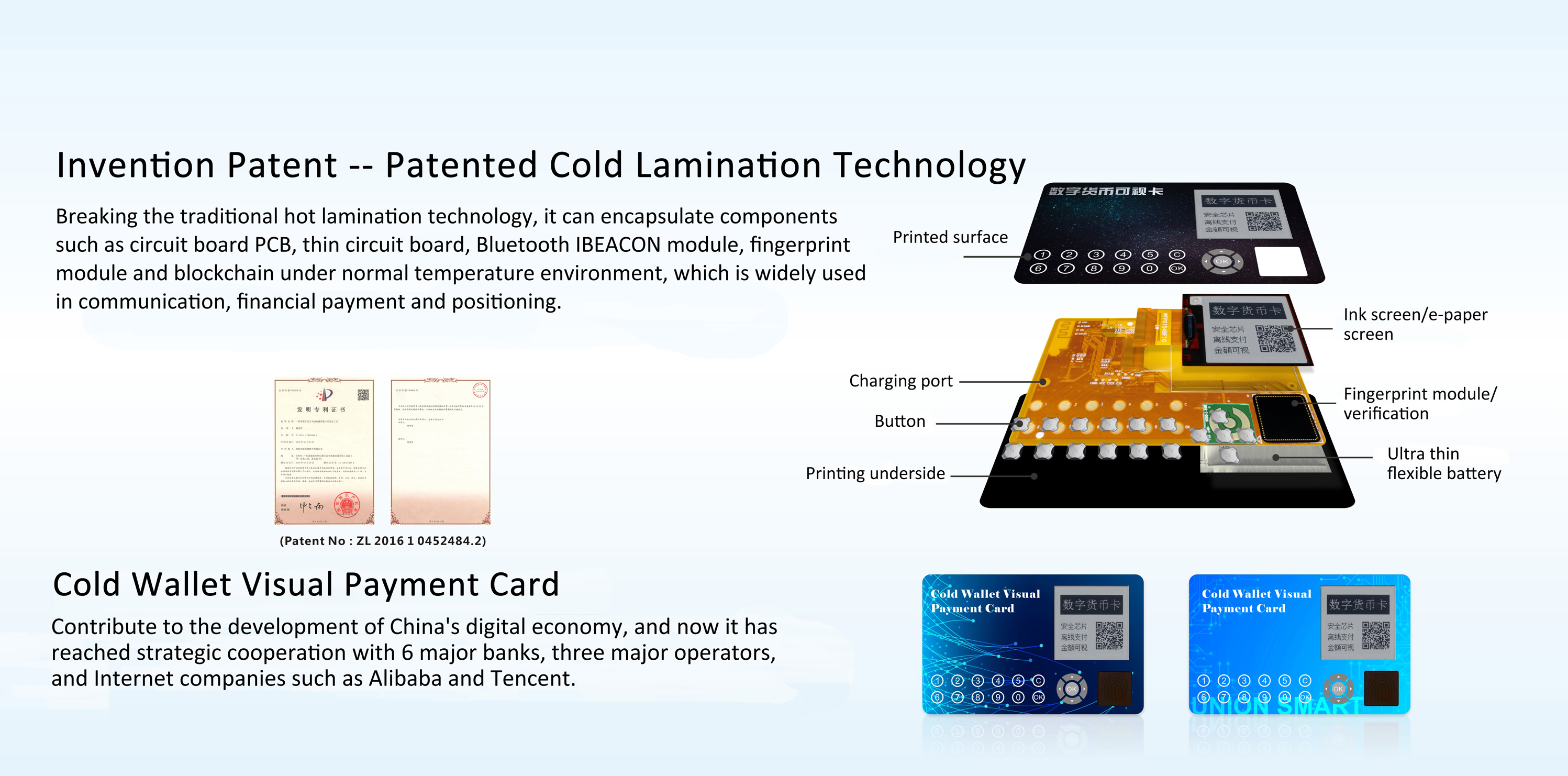

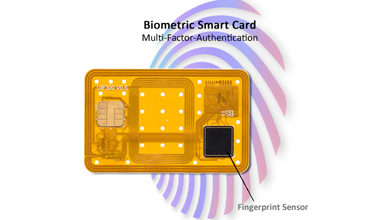

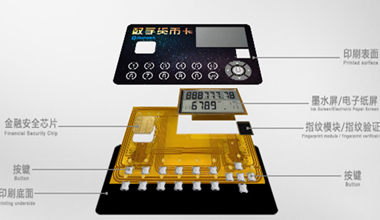

OEM/ODM Processing/ Lamination/Integration for Active Electronic Smart Card of biometric/authentic/IOT/OTP/FP developer Board

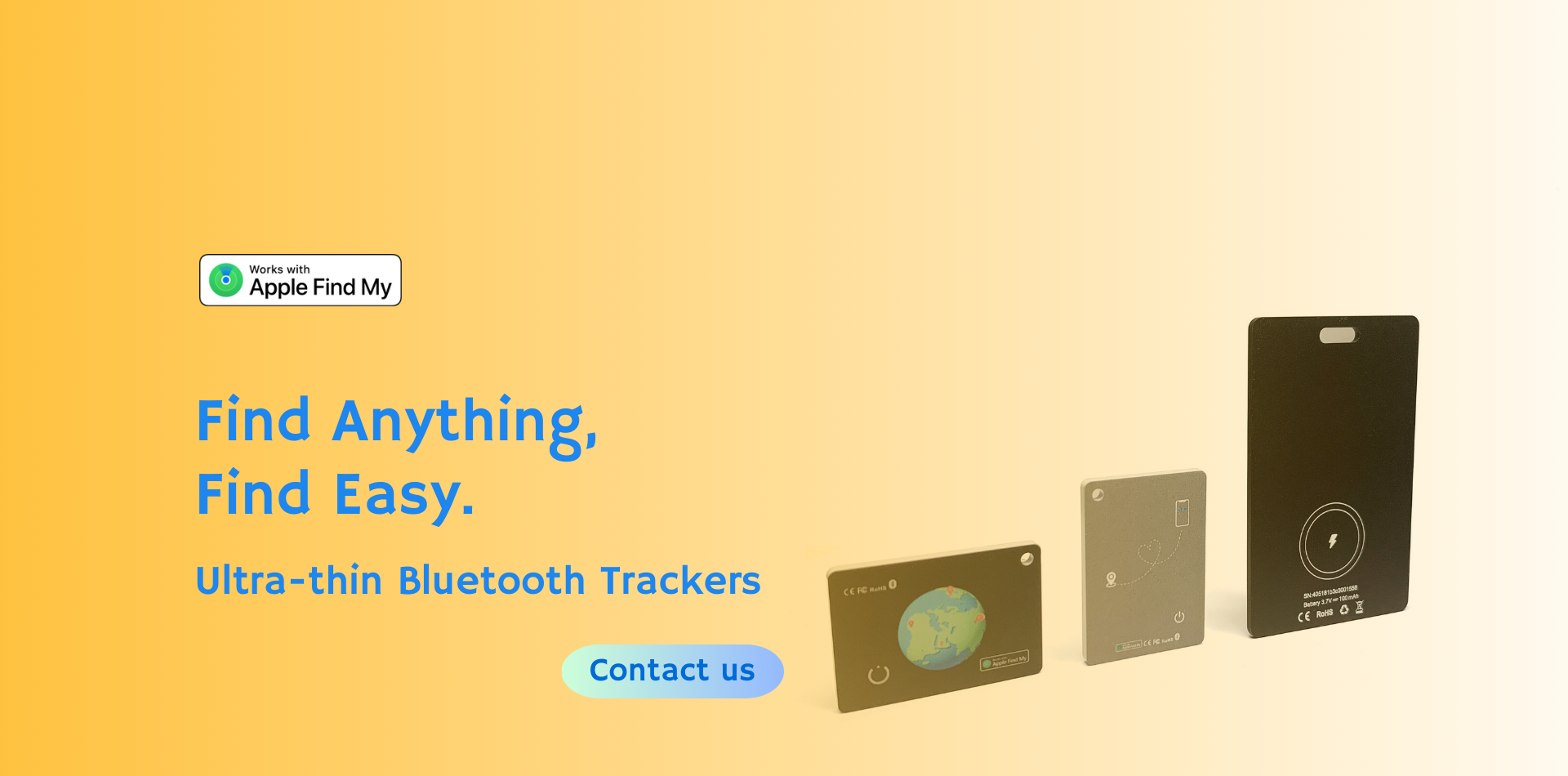

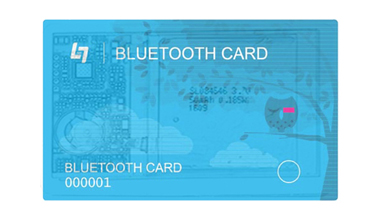

PCBA Bluetooth Application Card

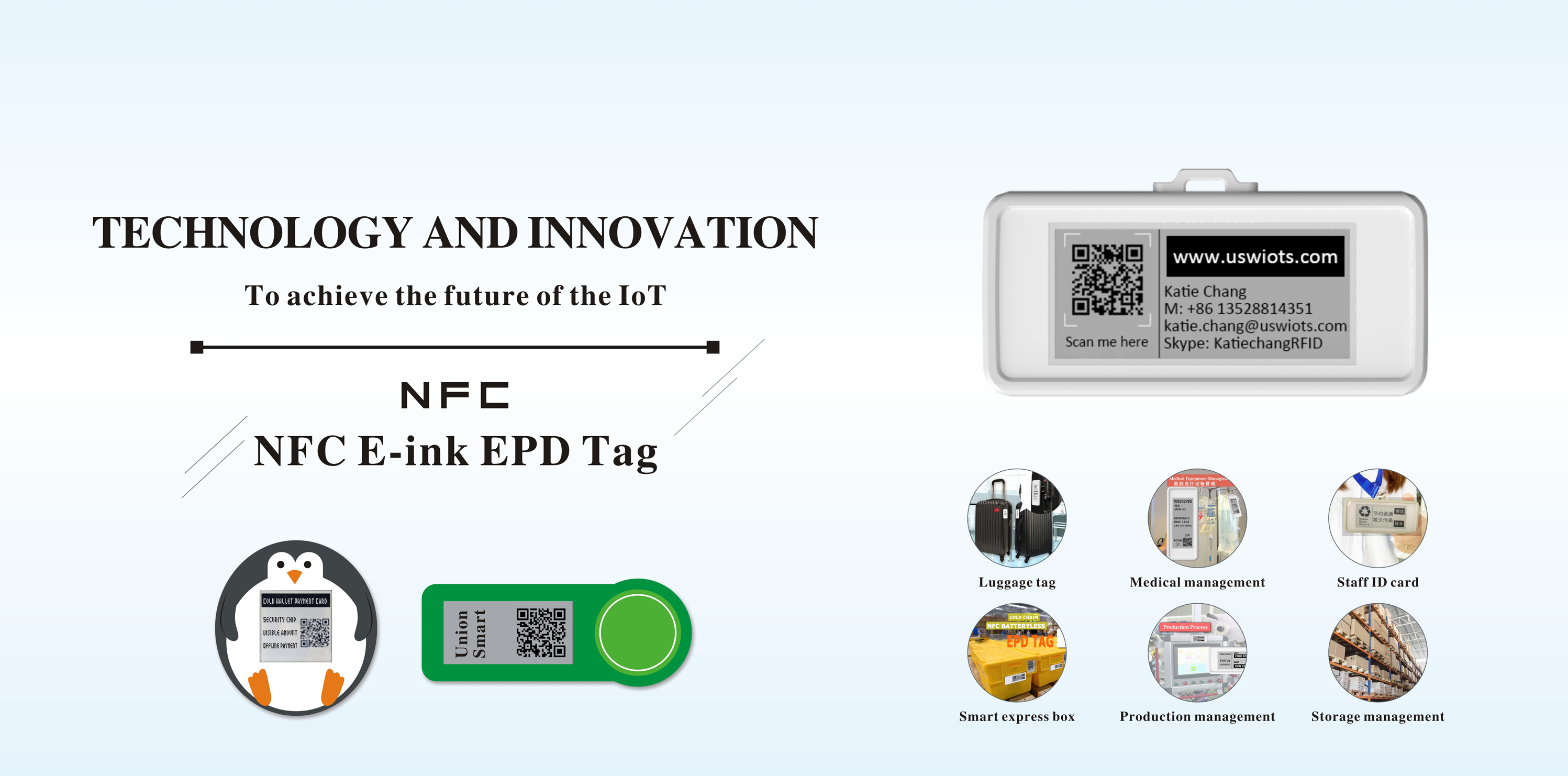

Batteryless NFC E-ink Tag

Interaction

Common Question Answers