CN

Products

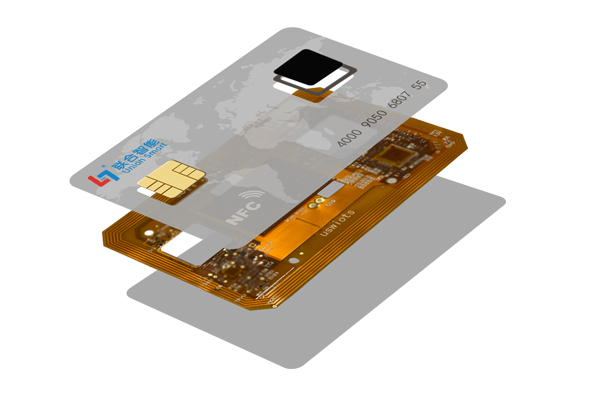

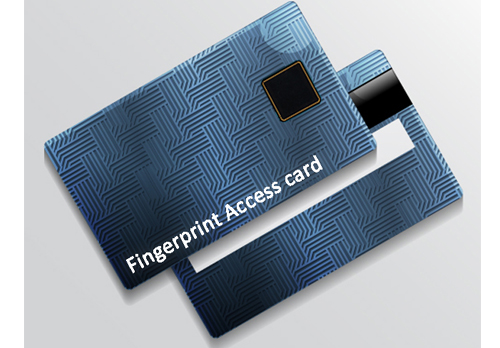

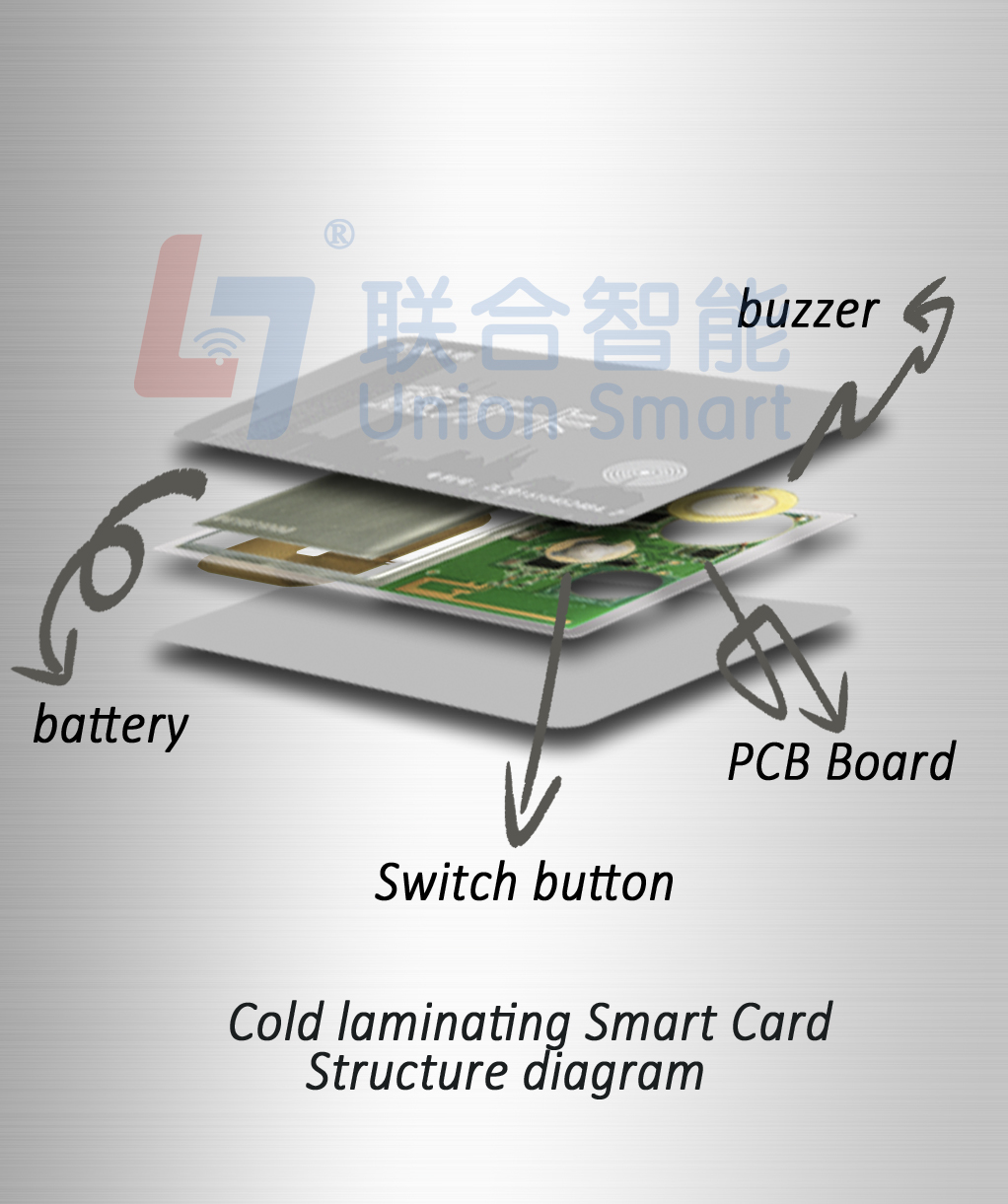

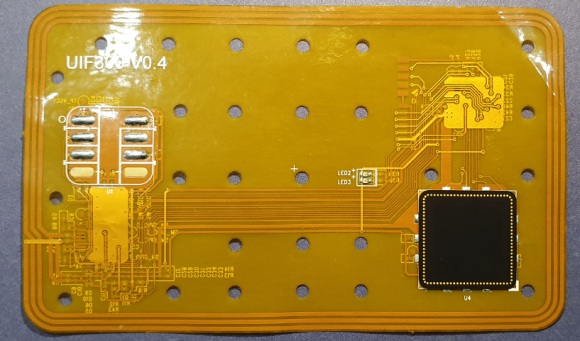

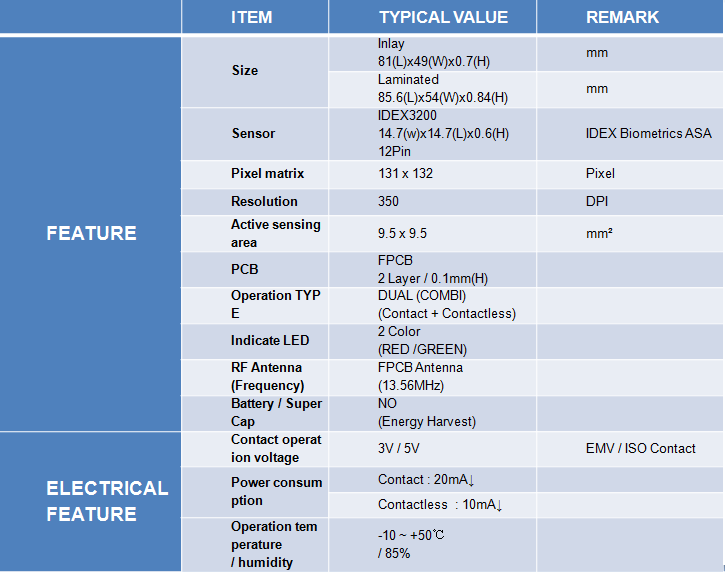

OEM/ODM Processing/ Lamination/Integration for Active Electronic Smart Card of biometric/authentic/IOT/OTP/FP developer Board

PCBA Bluetooth Application Card

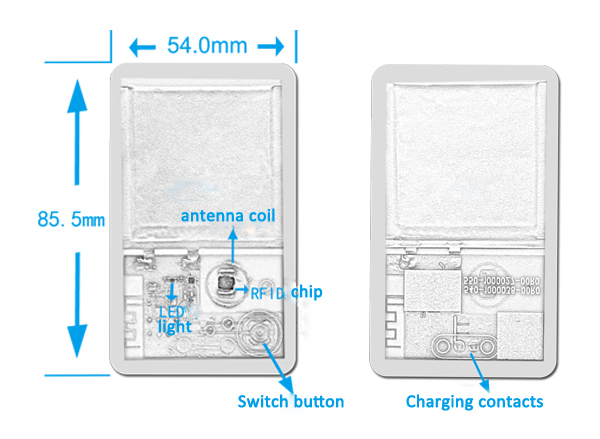

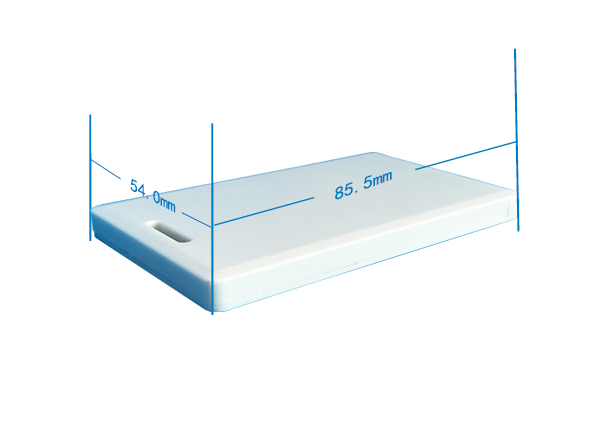

Batteryless NFC E-ink Tag

Interaction

Common Question Answers